Round cans

Pails

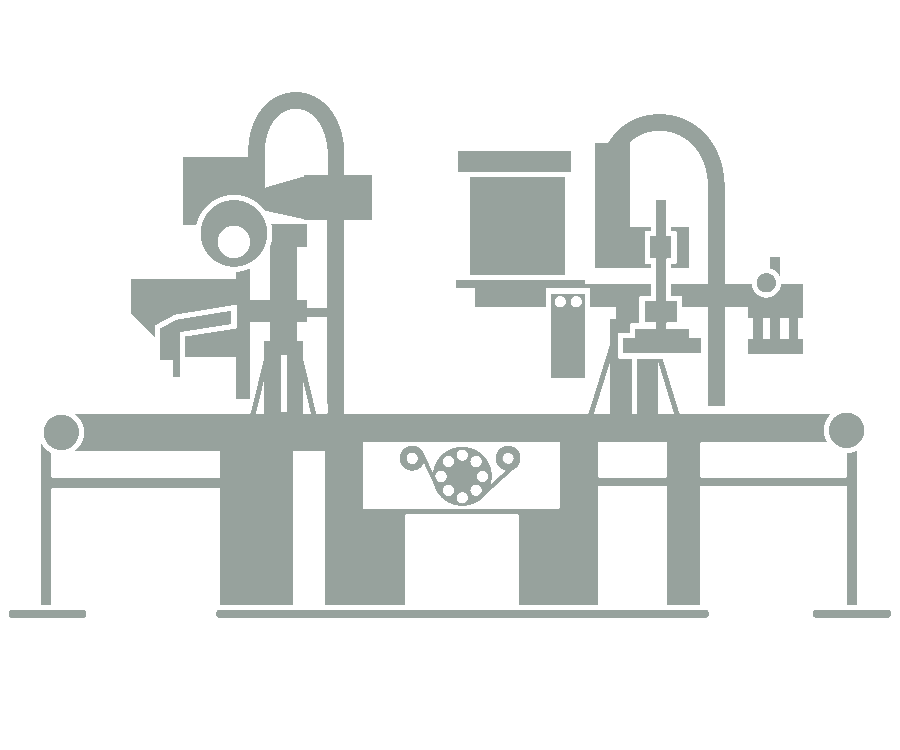

Maschines

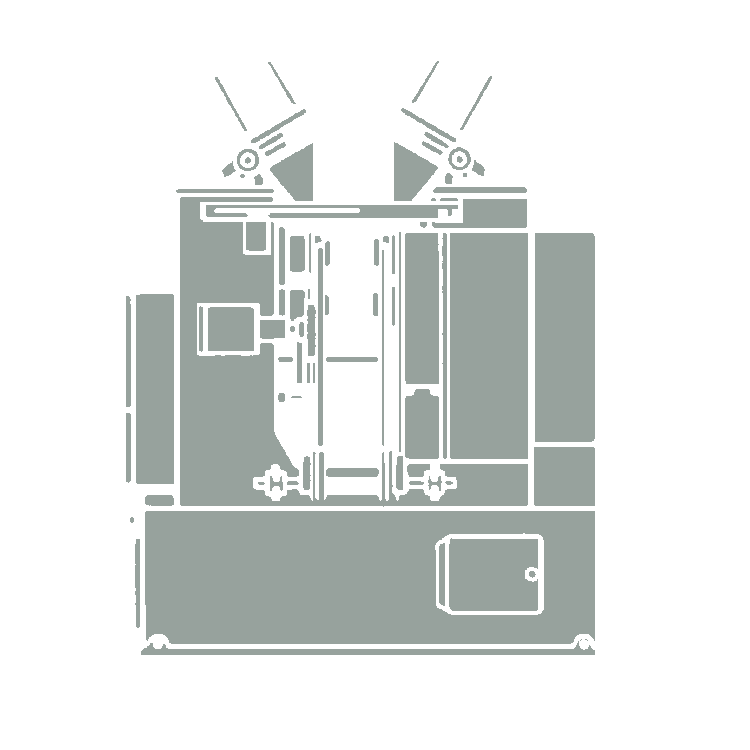

SFM2/22

The series of SFM stretch forming machines has been developed for stretch forming can bodies to meet the steadily increasing demands for higher output. The machine is based on the same principle as the well known and proven types of single and dual head stretch forming machines of the AFMR series.These machines are capable of stretch forming either soldered or welded can bodies. The final shape of the can is determined by the tools which are build for the machine: rectangular, oval, mandolin shaped, square with rounded ends or virtually any other shape within the limitations of the material used.

Specifications:

65/min till 130/min

100mm till 200mm

100mm till 400mm

up to 0.4mm

Functions:

Expanding

Seam locating

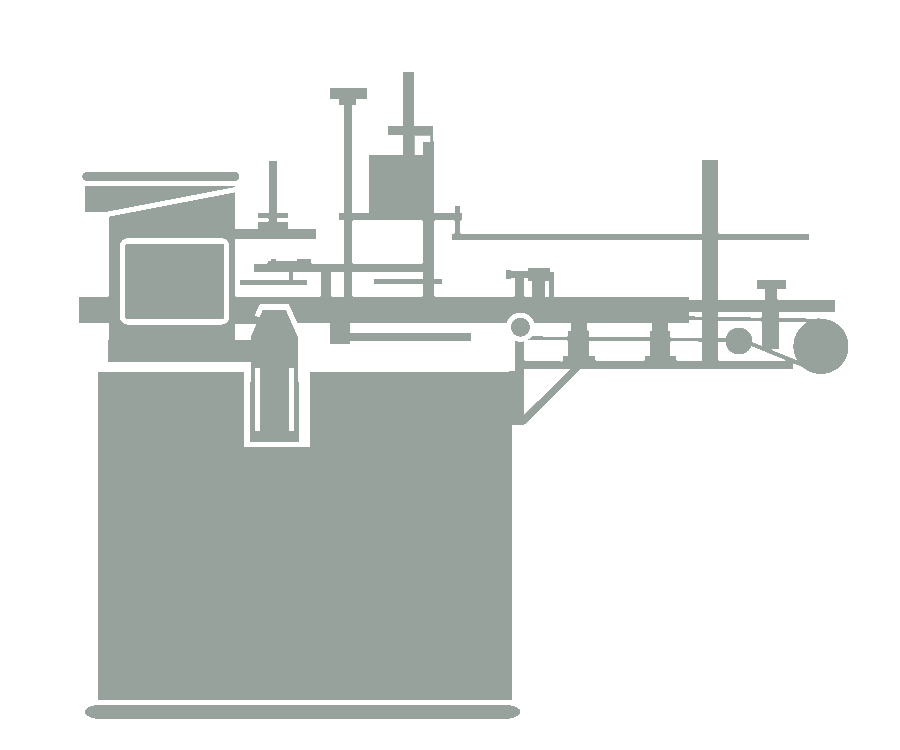

AFMR / AFMK / AFMP

The AFMR machine is designed for automatic forming of cylindrical, soldered or welded bodies. The body can be formed to rectangular, oval or pear-shaped cross-section, depending on the tooling mounted in the machine. The AFMR machine is designed with two stations. In the first station the cylindrical body is overlap-controlled, i.e. the overlap is always placed in right position in relation to the cross-section of the body or decoration, if any. The overlap can be placed 360° along the whole circumference of the body. In the second station a tooling is mounted. This tooling makes the design of the body.

Specifications:

20/min till 50/min

100mm till 350mm

100mm till 500mm

up to 0.4mm

Functions:

Expanding

Seam locating

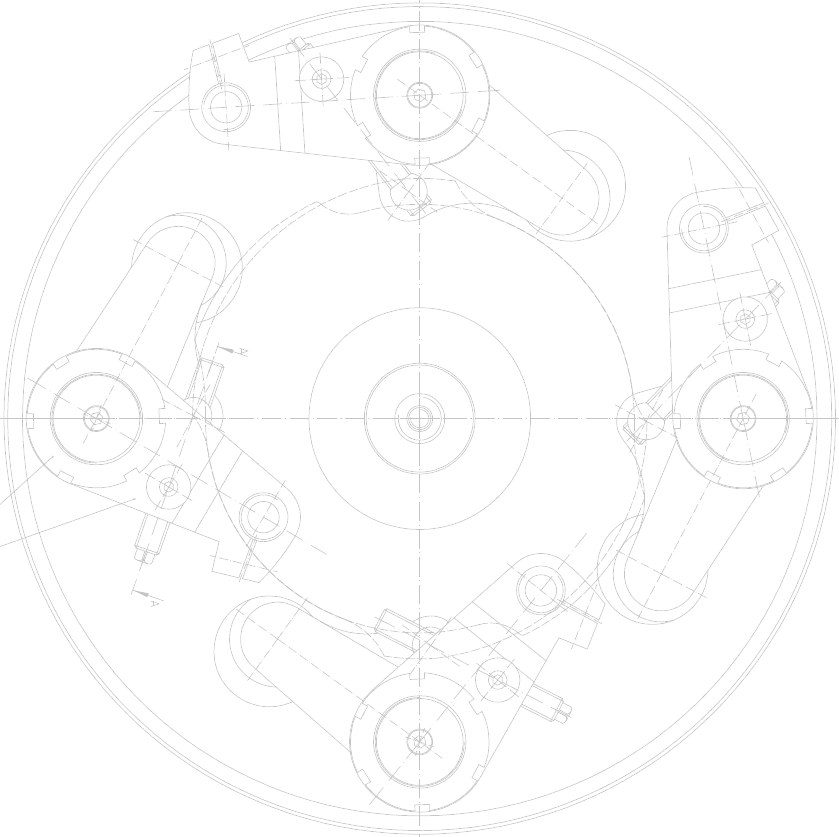

DFS 195

This automatic flanger and double seamer is used for the production of round cans of all kinds. Following designs are available:

- automatic flanger – bottom seamer

- spin flanger – bottom seamer

- roller flanger – necker – bottom seamer

- curler and/or bottom seamer

Specifications:

120/min

35mm till 130mm

50mm till 400mm

up to 0.4mm

Functions:

Die flanging

Spin flanging

Roller flanging

Necking

Curling

Seaming

DFS 250

This automatic flanger and double seamer is used for the production of round cans of all kinds. Following designs are available:

- automatic flanger – bottom seamer

- spin flanger – bottom seamer

- roller flanger – necker – bottom seamer

- curler and/or bottom seamer

Specifications:

70/min

99mm till 250mm

45mm till 400mm

up to 0.4mm

Functions:

Die flanging

Spin flanging

Roller flanging

Necking

Curling

Seaming

BHP 43

This machine is used for welding ears, type Larsen 5.3, automatically to round, cylindrical cans, and automatically forming and attaching bails made of plastic. The kind of welding process means that cans can be processed which are decorated or lacquered both on the inside and the outside.

-TV: The bails are attached in the same stage of production as the ears are welded, meaning that the bail is attached securely to the can and cannot detach itself.

-KV: The bails have a special hole at each end which means that the metal can and the plastic bail can be separated very easily later on for recycling.

Specifications:

70/min

140mm till 200mm

120mm till 350mm

up to 0.4mm

Functions:

Welding

Bailing

Lacquering

WB 53

This machine is used for welding ears, type Larsen 20-S, automatically to round, cylindrical or conical cans, and then automatically forming and attaching bails made of steel wire. The kind of welding process means that cans can be processed which are decorated or lacquered both on the inside and the outside. The design of the bail forming tooling means that, to a large extent, it is possible to produce customer-specific bail shapes.

Specifications:

70/min

125mm till 250mm

120mm till 350mm

up to 0.4mm

Functions:

Welding

Bailing

Lacquering

WB 50

This machine is used for welding ears, type Larsen 30-S, automatically to round, cylindrical or conical cans, and then automatically forming and attaching bails made of steel wire. The kind of welding process means that cans can be processed which are decorated or lacquered both on the inside and the outside. The design of the bail forming tooling means that, to a large extent, it is possible to produce customer-specific bail shapes. The bails can be provided with a plastic grip

Specifications:

50/min

200mm till 330mm

150mm till 500mm

up to 0.4mm

Functions:

Welding

Bailing

Lacquering

B 20-A

This machine is used for welding ears, type Larsen 20-S, automatically to round, cylindrical or conical cans, with automatic can separation and orientation and automatic ear separation and infeed. The kind of welding process means that cans can be processed which are decorated or lacquered both on the inside and the outside.

Specifications:

40/min

140mm till 250mm

100mm till 350mm

up to 0.4mm

Functions:

Welding

H 20

This machine is used for attaching wire bails automatically to round cans which have already been provided with ears, type Larsen 20-S, at an earlier stage in production. The following functions are fully automatic:

1. Separation of the cans which are transported by the customer’s own feeding belt (standing one behind the other in a queue, with random orientation of ears)

2. Search for, identification and positioning of ears.

3. Separation and infeed of positioned, pre-cut wires as well as forming and attaching the bail.

Specifications:

40/min

125mm till 250mm

100mm till 350mm

up to 0.4mm

Functions:

Bailing